Northern Gear & Machining is here to help you improve profitability by streamlining production, providing the lowest per piece cost, reducing warranty claims and meeting your delivery schedules. Our broad range of in-house services from engineering to quality inspection to testing to production and inventory management can help you ensure that your quality is consistent, costs are low and customers are always satisfied.

Engineering

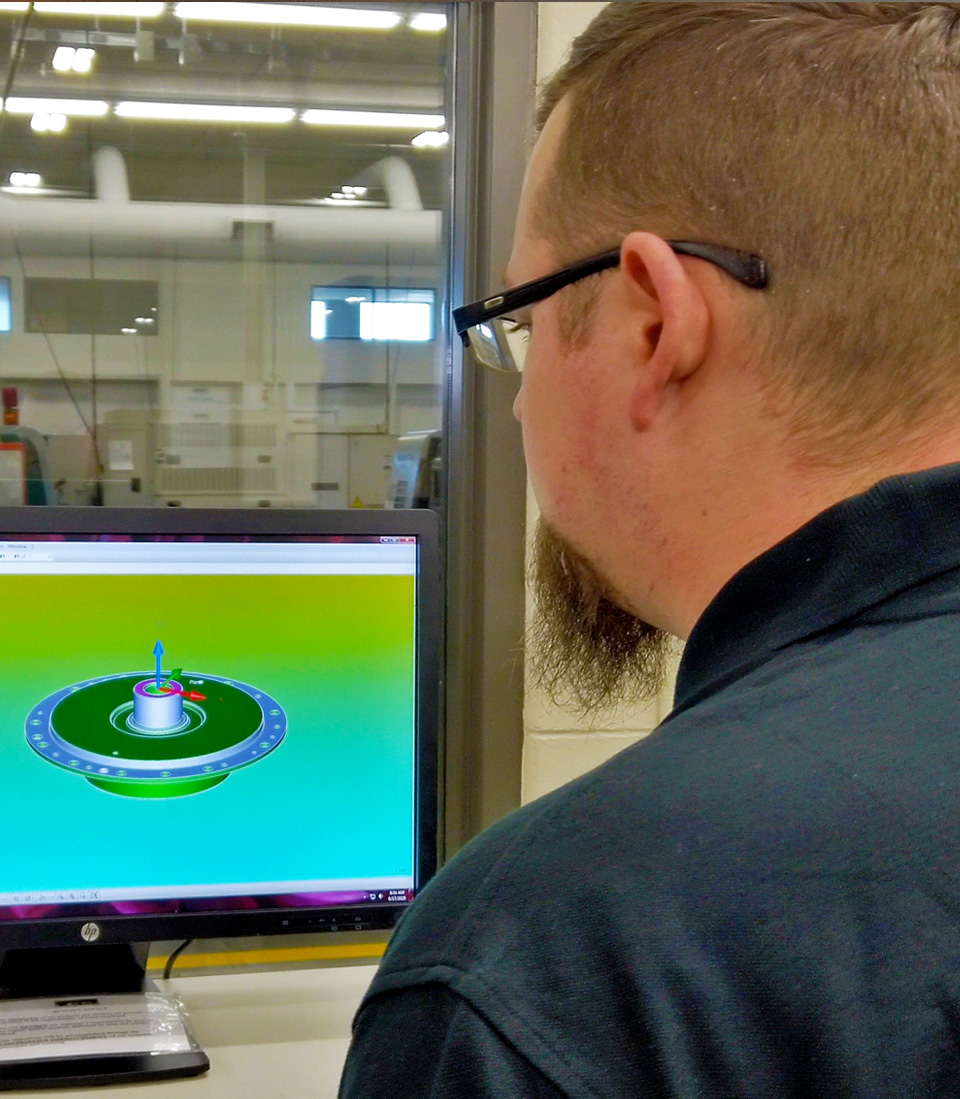

Northern Gear & Machining offers customers superior engineering and problem solving capabilities. Our team is made up of professionals from multiple engineering disciplines, and we can help develop co-engineered efforts with your team to create the solution you’re looking for. We are experienced in prototyping and will combine conceptual engineering know-how with your critical requirements and CPPD, (Concurrent Product/Process Development) to create a recipe that results in the highest quality solution at the lowest cost.

Quality Inspection & Testing

Quality Systems at Northern Gear & Machining are ISO Certified. We use state of the art systems to test finished components and assemblies for specification conformance and strength. We also perform metallurgical testing and cleanliness testing.

Supply Chain Management

Northern Gear & Machining offers several services to help you better manage production, inventory and delivery. Our EDI system enables clear communication with everyone in the supply chain regardless of their computer systems. Leveraging EDI, we can use Kanban, a lean production technique, and Just in Time (JIT) delivery to produce product according to what is ordered. We’ll then deliver it fast and on time, helping to shorten your delivery schedules and reduce inventory waste.